At Passenger Terminal T1 of Noi Bai International Airport, hundreds of meters of baggage conveyors tirelessly operate for nearly 18 hours each day. Few people know that behind that continuous motion once lay a great waste of electricity and a heavy dependence on foreign manufacturers. With intelligence and professional passion, the technicians of the Mechanical Team, Terminal Operation Center of Noi Bai, successfully solved this difficult problem, bringing an annual benefit of about 1.6 billion VND — and, beyond that, pride in mastering technology.

The team of authors behind the technical innovations worth billions for the unit: Nguyen Quoc Tien Thang, Nguyen The Toan, and Le Van Nguyen (from left to right).

The Challenging Problem Called “Dependence”

The Baggage Handling System (BHS) at Terminal T1 is a complex system, likened to the “circulatory system” of the terminal. However, for many years, this “lifeline” operated with inherent limitations due to complete dependence on its manufacturer, Beumer Group. Engineers and system operators were always in a passive position.

The SCADA monitoring and control interface — the “brain” of the system — was a “black box” that could not be modified. The airport’s technical staff could not change the layout or color of the display that showed the conveyor’s operation status, which often caused confusion. Even adding one additional monitoring workstation was impossible — the system was locked at two default stations. More seriously, if the main server encountered an error, the team could not fix it themselves but had to wait for specialists from the manufacturer. The risks were always there: if the server failed and stopped, the status of the entire system could not be monitored or controlled, leading to loss of oversight, safety risks, and serious impacts on service quality.

The SCADA monitoring and control system team.

In addition to software dependency, another visible waste occurred daily. According to the manufacturer’s control design, the entire system operated continuously from the first flight of the day to the last, and only stopped completely 15 minutes after the final flight. This meant the system ran idle for hours, wasting electricity, increasing operational costs, and reducing the lifespan of hundreds of motors and components.

Concerned about this situation, during a thematic Party meeting, the Mechanical Team’s Party Cell identified mastering technology and practicing thrift as a key political task. The Party Cell Secretary emphasized: “We cannot remain dependent forever. We must make full use of the intelligence of our own technicians, engineers, and Party members who are deeply attached to the machines.” That direction and timely encouragement sparked determination and inspired the engineers — Nguyen The Toan, Nguyen Quoc Tien Thang, and Le Van Nguyen — to begin a challenging journey: “decoding” technology to take control of the system.

Leading the team was Nguyen The Toan, Deputy Secretary of the Party Cell and Deputy Leader of the Mechanical Team. He shared: “It was tough at the beginning. Many nights after finishing our shifts, we stayed to find the root of the problem. Despite the hardship and limited resources, with our sense of responsibility as Party members and technicians, we told ourselves we had to succeed — not to disappoint our colleagues or leaders.”

The Journey of “Decoding” and the “Sweet Fruit” of 1.6 Billion VND

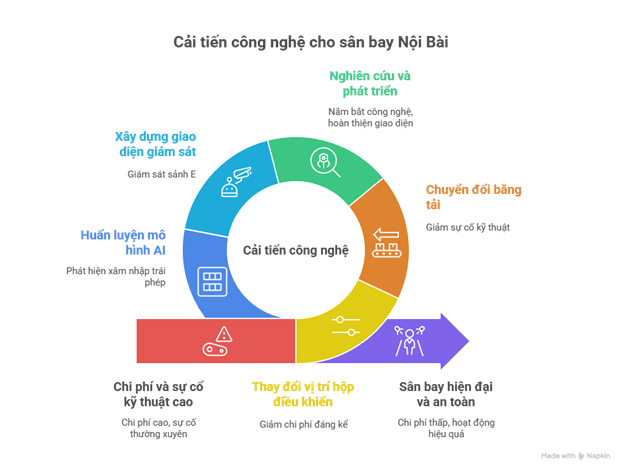

With the spirit of “daring to think, daring to act,” the team created a dual action plan: build a backup SCADA workstation to regain control and modify the PLC control program to save power.

Engineers diligently working on the backup SCADA workstation.

The journey of “decoding” the manufacturer’s technology was far from easy. It took long days and nights of studying, reverse-engineering complex code, and testing on simulated models. Through persistence and solid technical expertise, they successfully developed a backup SCADA workstation “made in Noi Bai” that operated effectively alongside the manufacturer’s system. This new “brain” returned control to the Noi Bai technicians. They could now adjust the system layout as needed, remove unnecessary functions, and add more suitable features. Dependence on Beumer Group was significantly reduced.

At the same time, the team discovered an “energy-saving gold mine.” They deeply modified the PLC program to add a crucial feature: automatic stop when no baggage was detected. A timer was set — after 30 seconds without a baggage signal, the conveyor automatically stopped; when baggage appeared again, it resumed operation.

Two engineers performing an electrical system inspection.

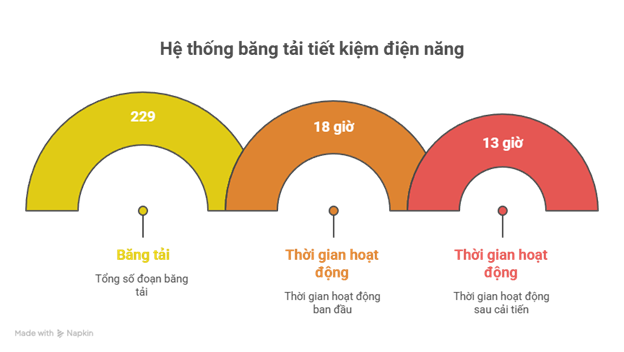

This seemingly simple solution brought results beyond expectation. After full deployment across 229 conveyor sections, the system’s daily operation time was reduced from 18 hours to just 13 hours — saving 5 hours of running time. Measurements showed that each conveyor, with an average power of 1.5 kW, saved about 6.5 kWh per day. The total electricity saved each month was 44,655 kWh, equivalent to over 133 million VND. Over a year, 535,860 kWh were saved, bringing an annual benefit of about 1.6 billion VND.

The innovation significantly reduced the system’s operating time.

The “sweet fruit” of this innovation was not only counted in money. It also meant autonomy in operation and repair, safer and more efficient systems, improved service quality, reduced industrial noise, and extended equipment lifespan — a sustainable benefit for the future.

The “decoding” journey of Noi Bai’s technicians was not only an economic achievement but also a vivid example of following President Ho Chi Minh’s teachings on thrift and anti-wastefulness. Inspired by those teachings, they created a concrete initiative that saves their unit 1.6 billion VND every year.

The Ripple Effect of a Creative Movement

The success of the SCADA and PLC project was not an isolated case but the inevitable result of a long-standing culture of innovation and creativity within the Mechanical Team and Noi Bai International Airport. The spirit of “daring to think, daring to act” has become a signature, spreading across numerous initiatives that generate major economic and social benefits.

A typical example was the repair of passenger boarding bridge tires. Instead of buying new ones for 350 million VND each, the team cooperated with domestic contractors to recoat the rubber layer for only 40–50 million VND, cutting costs by 85%.

Instead of importing entire passenger bridge tires, the unit only purchased new rubber layers, saving both cost and administrative procedures.

Another outstanding innovation was the improvement of the anti-collision protection gear for the 28 passenger boarding bridges at Terminal T2. The original Tape Switch sensors used by the manufacturer had many drawbacks when operating outdoors: short lifespan (around 4 years), complicated installation, and very high cost — nearly 30 million VND per sensor. Facing the dual challenge of ensuring safety per Vietnam Civil Aviation Authority regulations and optimizing cost, the Mechanical Team successfully designed a replacement using limit-switch mechanisms. This “made in Noi Bai” solution offered superior durability with IP67 dust- and water-resistance, suitable for harsh weather, while costing only 4.3 million VND per set. The innovation not only gave Noi Bai full control over maintenance and improved safety for 28 existing bridges but could also be applied to future T2 expansion projects.

Smiles of engineers upon seeing the first results of their hard work.

A series of other improvements further demonstrate the team’s intelligence and technical mastery: relocating OP VDGS control boxes reduced costs from 72 million to 6 million VND each; converting curved conveyors (costing 90–150 million VND) into straight conveyors using domestic materials reduced technical incidents and expenses.

A Mechanical Team engineer inspects the passenger bridge wheel system.

These figures speak volumes about a team that constantly strives to turn challenges into opportunities. They have proven that Vietnamese workers are fully capable of mastering complex technologies, optimizing operations, and creating breakthrough value.

Looking Toward the Future

Although they have achieved remarkable success, the team is not stopping there. Their passion for innovation continues to burn brightly. Their next goal is to fully master the entire baggage handling system, completing the monitoring and control interface for Terminal T1. Beyond that, they are developing an AI-based system to detect unauthorized human intrusion into baggage conveyors at Terminal T2, contributing to aviation safety and security.

Deputy Team Leader Nguyen The Toan shared: “Our solution has been operating stably for more than a year now. We are continuing to develop new features, such as utilizing existing cameras integrated with artificial intelligence to detect when a person enters the conveyor area — the system will immediately stop.” He added that this idea is still being fine-tuned and tested before full deployment to enhance baggage handling safety at Noi Bai Airport.

Noi Bai International Airport is steadily innovating toward sustainable development through the thinking and efforts of ordinary people.

The story of the Mechanical Team of Noi Bai’s Terminal Operation Center — and of Noi Bai International Airport as a whole — shows the pivotal role of Party organizations in awakening the potential and intelligence of workers. It is a story of ordinary people who dedicate themselves day and night, transforming love for their profession and a sense of responsibility into billion-VND innovations, contributing to a more modern, self-reliant, and sustainable Noi Bai International Airport.